Before the foundation is poured or the first piece of structural steel is set for the new education and research building on the UMass Medical School Worcester campus, work has begun on a geothermal heating and cooling system that will reduce greenhouse gas emissions from the building by 55 percent compared to serving its HVAC needs exclusively with the campus power plant.

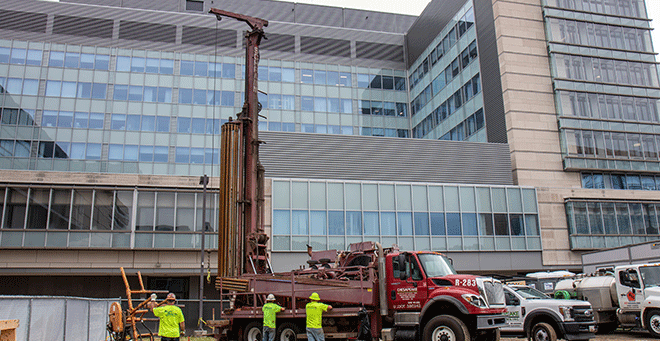

Borehole drilling (seen here) began on July 1 and is expected to continue through the summer. Once complete, the entire system of boreholes and pipe loops will be buried deep under the turf.

Geothermal systems work by circulating water through pipe loops buried deep in the ground. The heart of the geothermal system for the new building is an array of 75 boreholes, each six inches in diameter and 500 feet deep, drilled into the bedrock below the campus green. Water circulating through a closed-loop system of pipes in those holes will help to heat and cool the new building. Borehole drilling began on July 1 and is expected to continue through the summer. Once complete, the entire system of boreholes and pipe loops will be buried deep under the turf.

“This is an important sustainability milestone for the Worcester campus,” said John Baker, associate vice chancellor for facilities management. “It’s a big step toward meeting our long-term decarbonization goals.”

The campus power plant will supply electricity to the new building. The plant will also help meet peak demands for heating and cooling during the winter and summer months. Over the course of a year, the geothermal system will provide 88 percent of the heat for offices, laboratories, and educational and public spaces, and 50 percent of the cooling needs for the building.

If the new building were served exclusively by the campus power plant, it would generate approximately 3,000 tons of greenhouse gas emissions annually. The geothermal system will cut that carbon footprint by 1,660 tons per year, according to an energy analysis of the building conducted by engineering consultants BR+A.

The geothermal system for the new building will exceed the latest “stretch” building codes for energy efficiency and is aligned with the goals for new public buildings expressed in the state’s Executive Order 594 “Leading by Example: Decarbonizing and Minimizing Environmental Impacts of State Government” issued by Governor Charlie Baker on April 22.

Technically called a hybrid ground-source heat pump system, the technology works on the same principle as a window-mounted air conditioner that blows air across tubes filled with a refrigerant under pressure to cool the air in a room and sends the hot air outside. Now imagine if that window air conditioner sat on a turntable and could be flipped around on demand, so that the cold air blows outside and the hot air blows into the house. That’s essentially how the geothermal heat pumps will warm and cool the new building.

A window-mounted air conditioner transfers heat from the ambient air of your house. A geothermal system transfers heat energy stored in the ground. Once you get a few feet deep, the ground remains at a constant temperature, about 50 degrees in our region, all year long. That’s one of the reasons the basement of a house is cooler than upper floors, even on the hottest days of summer.

The steady level of heat underground—50-degree soil, rock or even air has a lot of heat in it—is captured by water circulating in U-shaped pipes grouted into each of the 75 boreholes. Warm water flows into the building, then returns to be cooled in the ground.

The holes are 500 feet deep to give the water sufficient time in the ground to exchange heat. Seventy-five boreholes are needed to supply enough water for the system.

A drilling rig will use an impact head to displace the rock and soil. The hole will be lined with a steel casing and water pumped through during drilling to flush soil and rock to the surface. The U-shaped pipe will be lowered and fixed in place with a special grout designed to conduct heat energy efficiently.

A network of horizontal pipes will connect the boreholes to a series of heat pumps in the building. Water from the boreholes will circulate through one side of the heat pumps, while a second closed loop system of water circulates through the other side of the heat pumps, to carry either chilled or heated water up.

Nested between each of the closed loops of water is a compressor coil filled with a refrigerant which exchanges the heat. Higher pressure in the coil raises the temperature. Lower pressure in the coil chills the water.

Each heat pump will have reversing valves, able to change the flow of heat exchange back and forth. Almost every day, some areas of the building will require heat and others cooling to maintain appropriate temperatures. The flexibility of the system allows some heat pumps to be in heating mode, while others operate in cooling mode, at the same time.

“The constant temperature of the ground is like having a head-start to heat the building and an ice chest to cool it off,” said Suzanne Wood, associate director, sustainability and campus services. “With a relatively low input of electricity to power the pumps and compressors, it keeps the building in proper balance and dramatically reduces the need for burning fossil fuel.”

Related story on UMassMed News:

Excavation begins for new education and research building