Fume Hood and Ventilation Changes at LRB Net Savings

A year of data is in, and the results are green. Improvements made to the air handling system and laboratory fume hoods at the Lazare Research Building (LRB) have reduced costs and energy consumption.

All the air moved through the laboratories in the LRB is drawn fresh from the outside, not partially recycled from within the building. Fresh air is filtered, humidified, heated or cooled as needed, then delivered to the labs and ultimately exhausted to the atmosphere. The single-use approach is important for research laboratories, but it utilizes more energy than a standard commercial system.

|

||||

|

|

“It’s very expensive air we exhaust, so our goal was to reduce the volume of air we use at the LRB while maintaining a safe and comfortable environment inside,” said David M. MacNeil, PE, senior mechanical project manager at UMass Chan who oversaw the ventilation project.

The project began with a detailed analysis of the ventilation system and measurements of the amount of air moving through the building. Engineers found that after more than 12 years of operations, the 10-story LRB had strayed from its optimal air flow settings. Furthermore, retrofitting the building with new technologies could increase the efficiency of the building beyond its initial design specifications.

“The team went through the building with a fine-tooth comb,” MacNeil said.

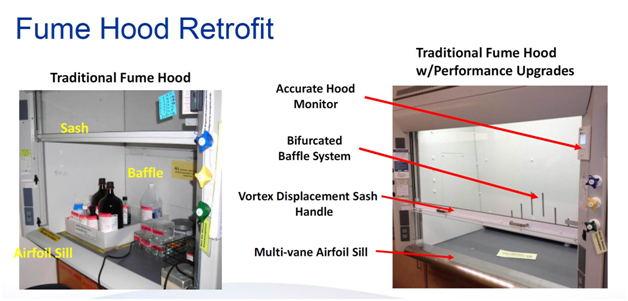

After the analysis, the school launched a $1.7 million project in early 2013 to improve the ventilation system and make changes to the 109 laboratory fume hoods that exhaust air and gases from research agents and processes. An air quality monitoring system was also installed throughout the building with new diagnostic and reporting tools that help the facilities staff keep the LRB operating safely at top efficiency.

The retrofitting work wrapped up at the end of 2013 and since then the monitoring data shows major savings. The air exchange rate in the laboratories is now 4.5 times per hour on average, down from as much as 10.2 changes per hour before the project. The velocity of air moving through the fume hoods is down from 100 feet per minute to 70 feet per minute. Overall air used in the building is down some 25 percent, with no impact on air quality.

As part of their own energy savings initiatives for laboratory buildings, the school’s electric utility providers partnered with UMass Chan on the project from the start, helping design the engineering audit and the retrofitting plan. Upon completion, the school received incentive payments of $560,000 from National Grid and $350,000 from NSTAR, helping to offset much of the project’s capital costs.

Plus, after nearly a year of operations, the LRB improvements have saved $518,000 in energy costs by reducing the amount of air used by the building. This will be an annual savings, MacNeil notes, so the pay-back period for the entire project was less than two years.

“This was an excellent project. It’s the type of opportunity we hope realize in other areas of the campus in the years to come so we can continue to reduce our energy consumption and carbon footprint,” said Suzanne Wood, sustainability and energy manager at UMass Chan. “We’re already working on the assessment phase for the biotech buildings off Plantation Street.”